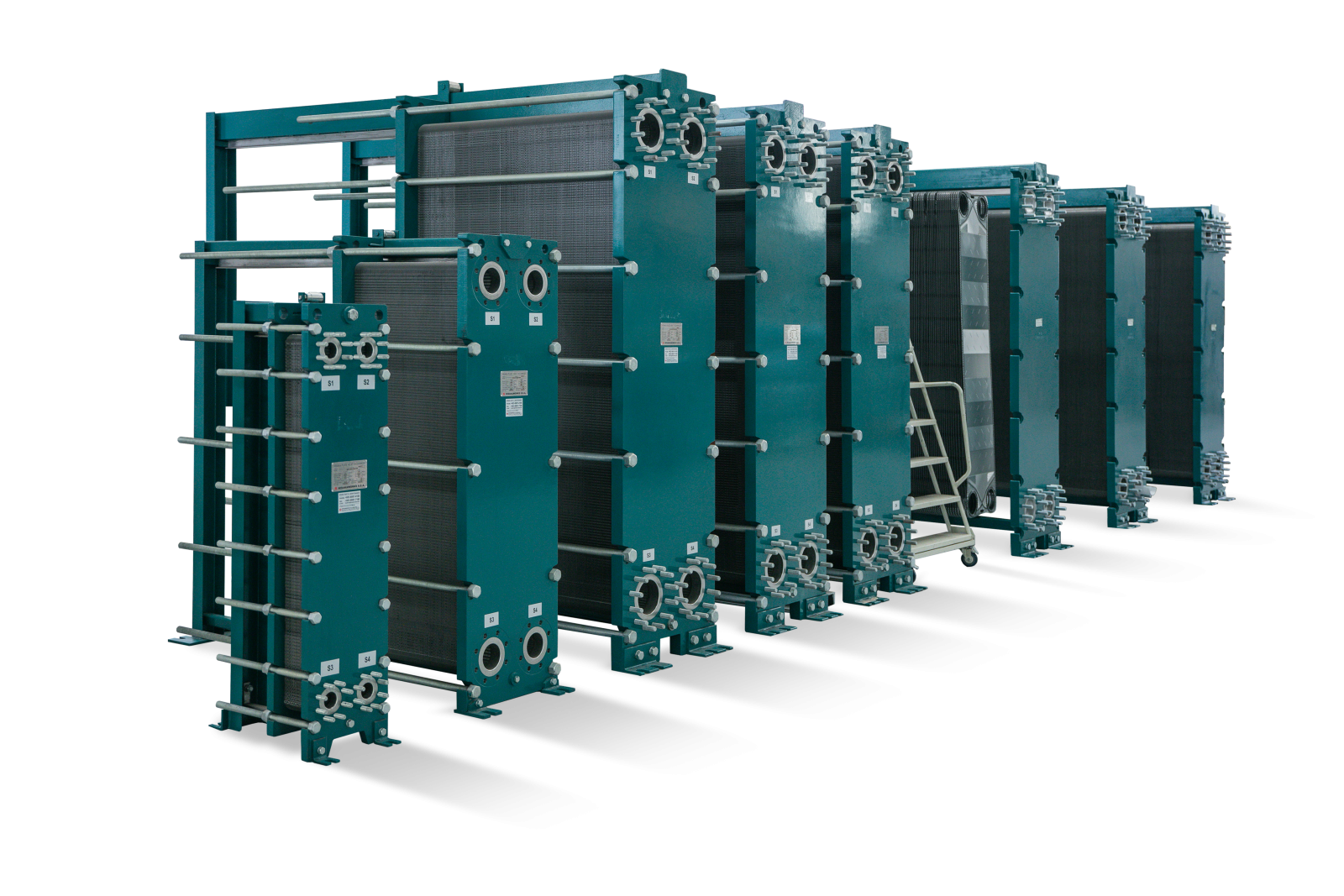

Plate Heat Exchanger Teknik Elektro

A plate-fin heat exchanger is a type of heat exchanger design that uses plates and finned chambers to transfer heat between fluids, most commonly gases. It is often categorized as a compact heat exchanger to emphasize its relatively high heat transfer surface area to volume ratio. The plate-fin heat exchanger is widely used in many industries, including the aerospace industry for its compact.

How plate heat exchanger work Alfa Laval

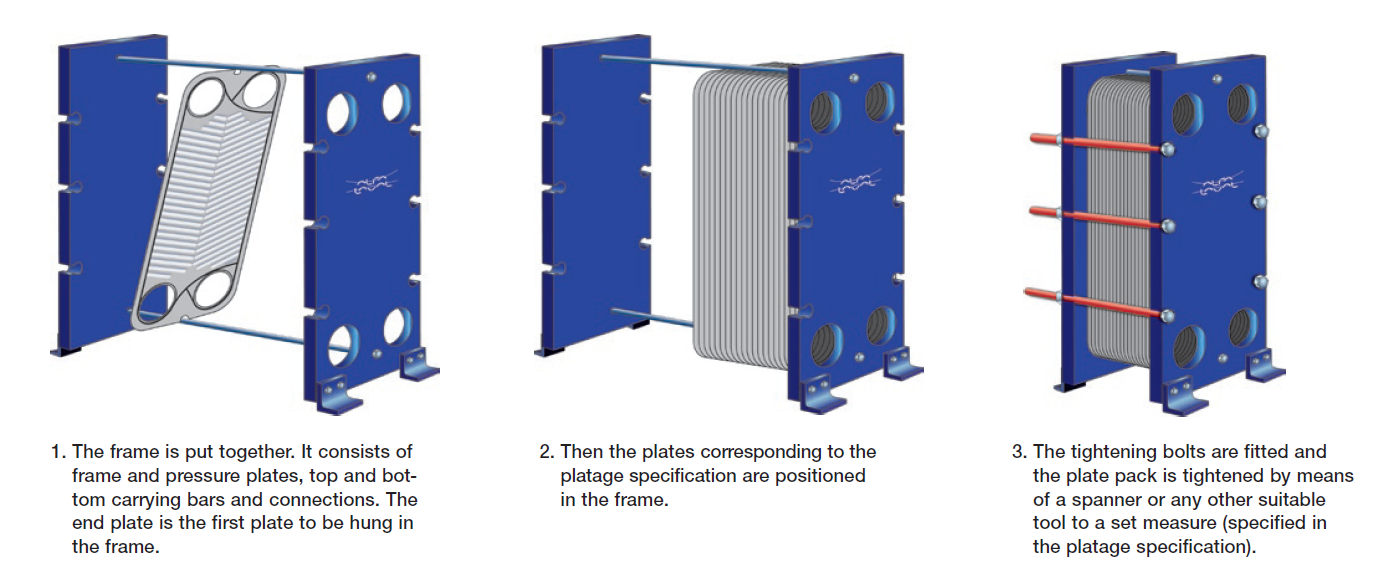

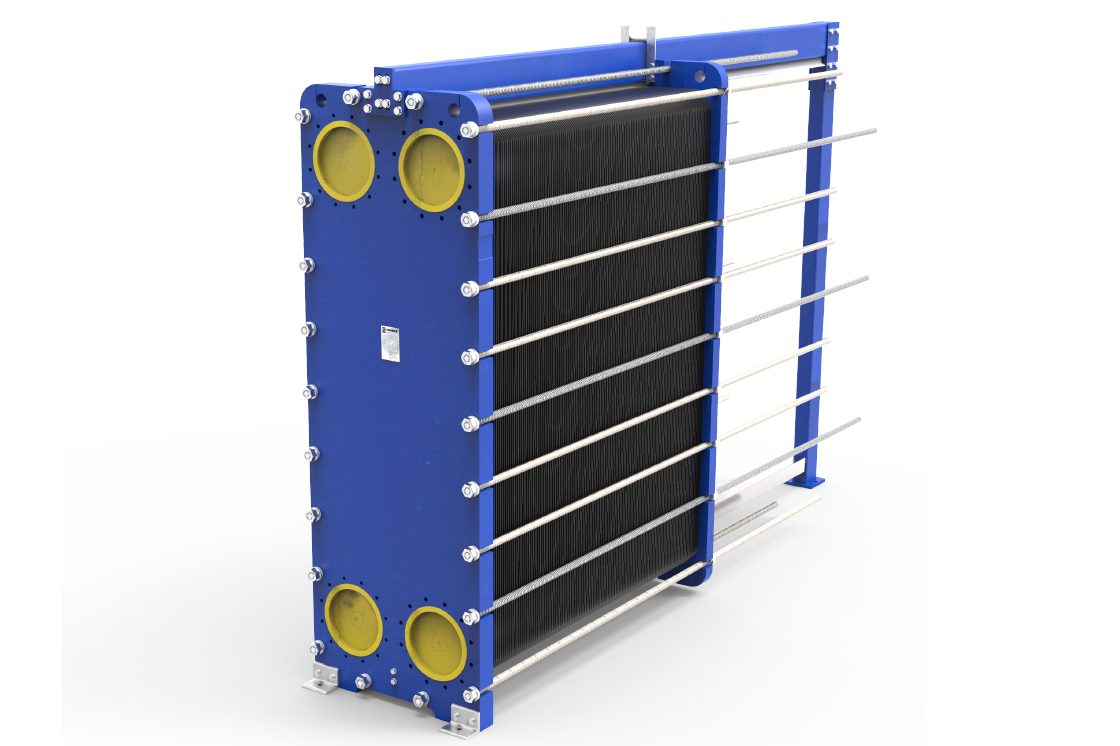

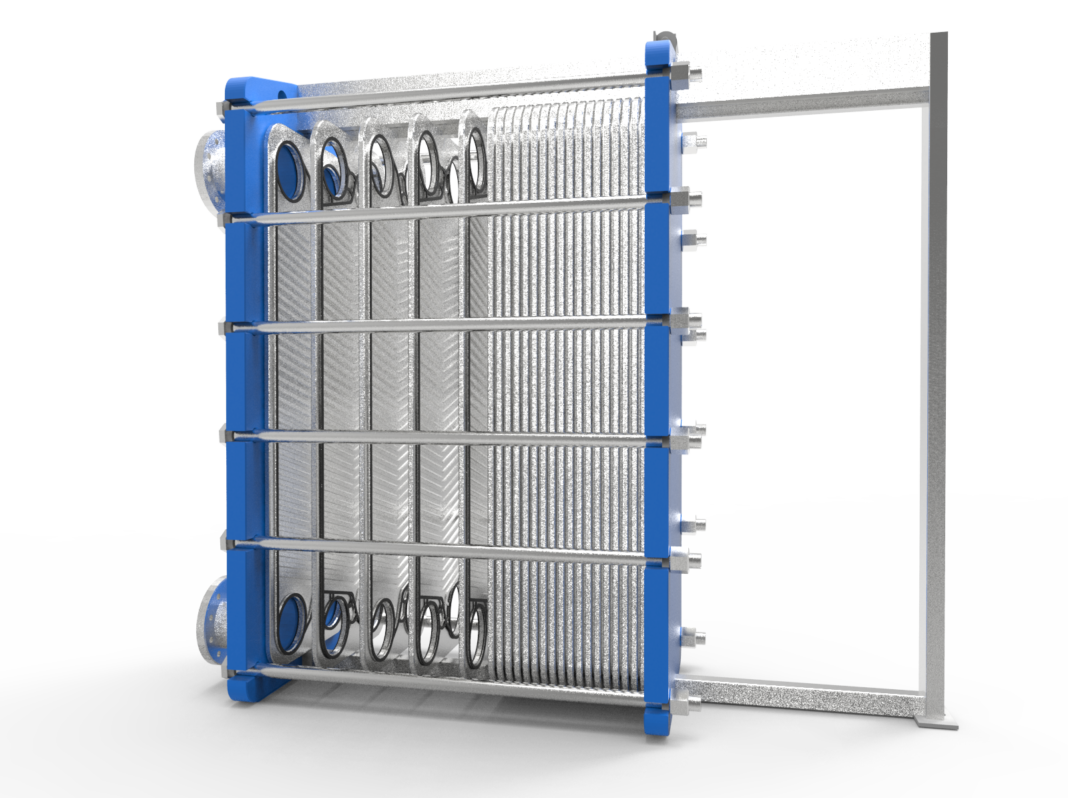

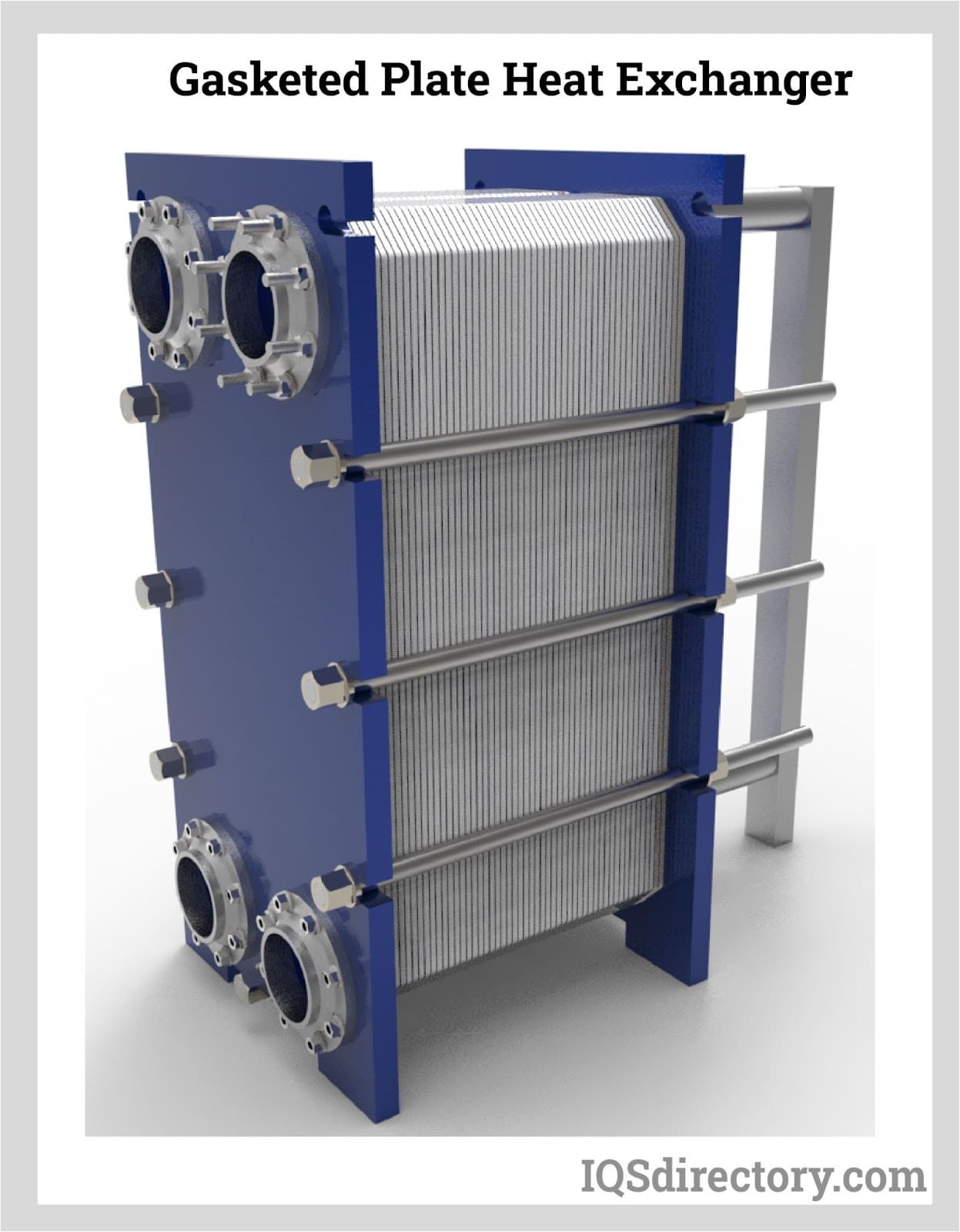

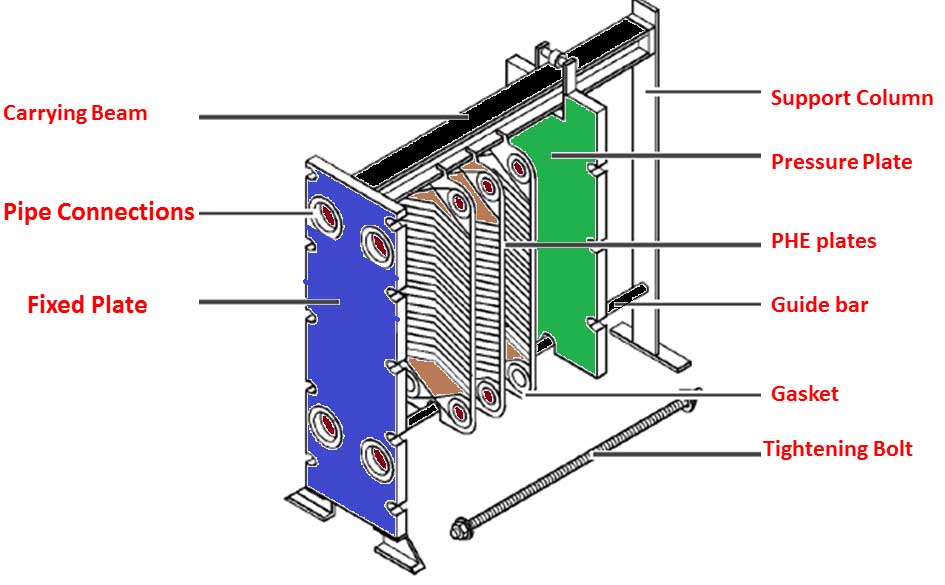

The plate heat exchanger is just one method of transferring heat between two fluids, and are especially useful for heat transfer between two liquids. Examine the plate heat exchanger shown in Figure 1. The blue plates shown are the front and end covers that sandwich many corrugated metal plates together, which are sealed with rubber gaskets.

Plate Heat Exchanger Types and Working Principles Linquip

Plates are pressed in materials between 0.5 and 1.2 mm thick and plates are available with effective heat transfer area from 0.03 to 3.5 m 2. Up to 700 plates can be contained within the frame of the largest Paraflow exchanger, providing over 2400 m 2 of surface area. Flow ports and associated pipework are sized in proportion to the plate area.

Plate Heat Exchanger Types and Working Principles Linquip

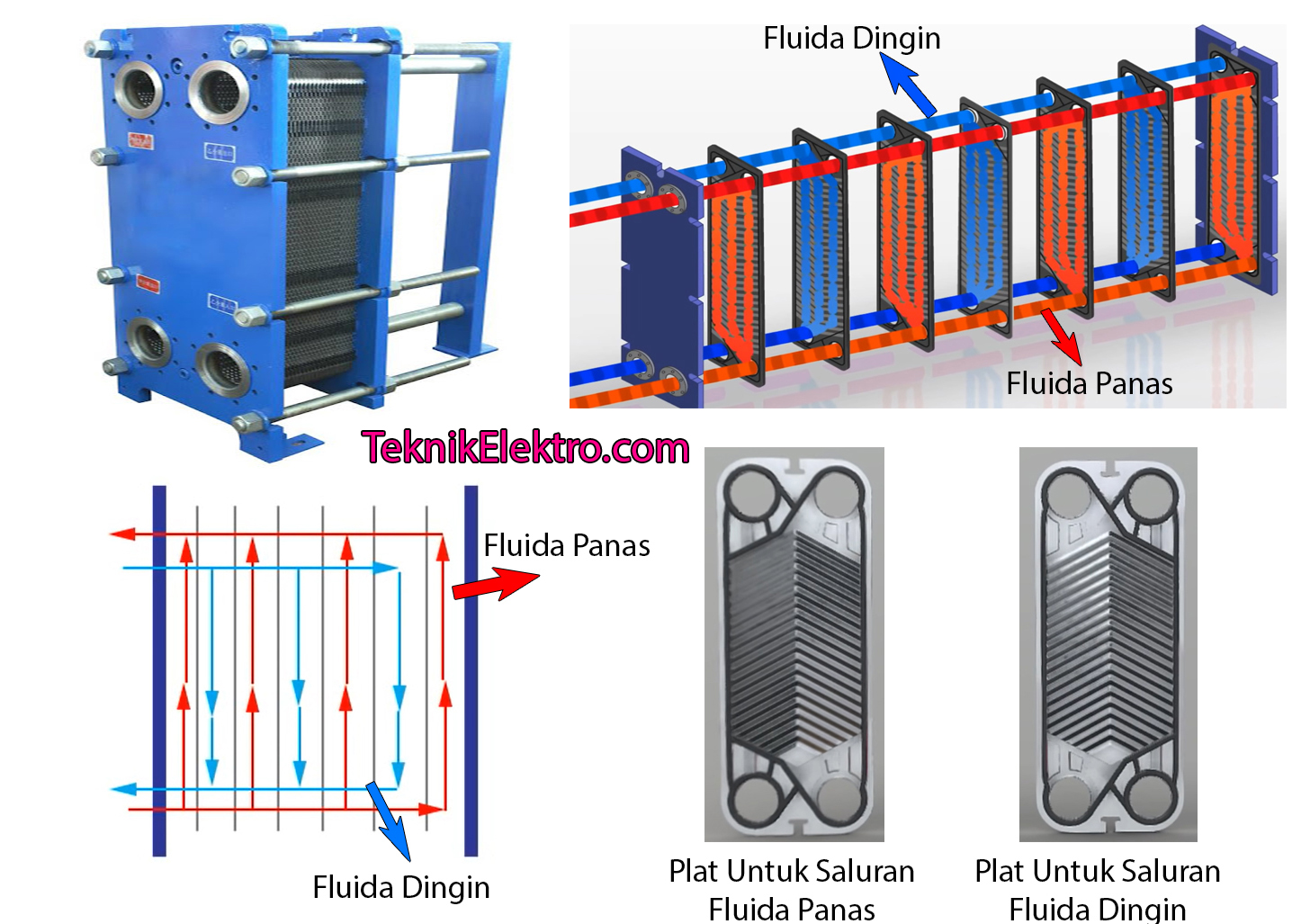

Plate Heat Exchanger adalah suatu media pertukaran panas yang terdiri dari Pelat (plate) dan Rangka (frame). Dalam Plate Heat Exchanger, pelat disusun dengan susunan tertentu, sehingga terbentuk dua jalur yang disebut dengan Hot Side dan Cold Side. Hot Side dialiri dengan cairan dengan suhu relatif lebih panas dan Cold Side dialiri dengan.

Plate Heat Exchangers Components, Types, Applications and Advantages

The Alfa Laval HEXpert selector tool makes it quicker than ever to find your ideal heat exchanger. Just answer a few short questions and get a customized recommendation to meet your unique needs. The tool currently covers products for design pressures up to 100 bar and design temperatures up to 450° C. Try the HEXpert selector tool.

Plate Heat Exchanger (PHE) Explained saVRee saVRee

The working principle of a plate heat exchanger is determined by its construction, function, and application. A plate heat exchanger is a class of heat exchangers for transferring heat between two fluids using metal plates. The plate heat exchanger has a notable advantage over conventional heat exchangers because the fluids are exposed to a.

Plate Heat Exchanger Applications The Engineering Mindset

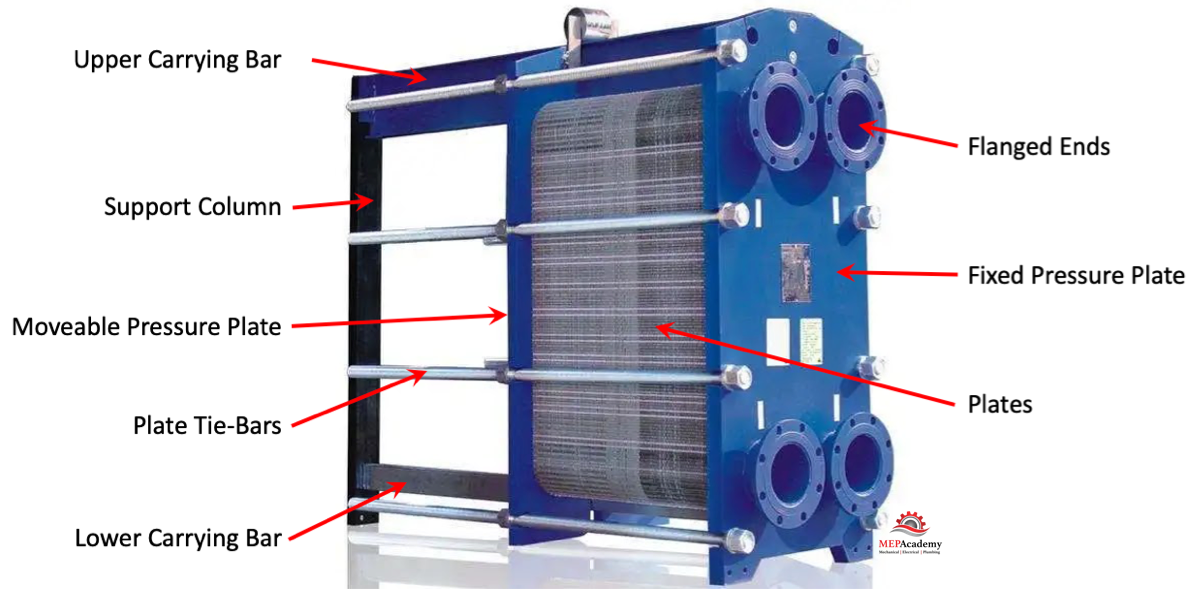

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids.This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change.

Plate Heat Exchanger Equals Higher Energy Efficiency The Washington Note

Bearing box, pada plate heat exchanger adalah komponen yang bentuknya lubang-lubang, yang menyangga lempengan pelat. Sedangkan frame foot fungsinya juga menyangga, tetapi posisinya di sisi bawah heat exchanger. Saluran pipa; Saluran pipa fungsinya adalah tempat yang menjadi akses fluida untuk keluar masuk.

Plate Heat Exchanger Types and Working Principles Linquip

The plates are 0.02 to 0.04 in (0.6 to 1 mm) thick. The size of the individual plates ranges from a minimum of approximately 0.5 ft x 1.5 ft (0.15 m x 0.46 m) to as large as 4 ft x 10 ft (1.220 m x 3.05 m). Plate and frame exchangers have heat transfer surface areas ranging from 5 to 13,000 ft2 (0.5 to 1210 m2).

Plate Heat Exchanger (PHE) Explained saVRee saVRee

With a plate heat exchanger, heat cuts through the surface and separates the hot medium from the cold. Thus, heating and cooling fluids and gases use minimal energy levels. The theory of heat transfer between mediums and fluids happens when: Heat is always transferred from a hot medium to a cold medium. There must always be a temperature.

How Plate Heat Exchangers Work The Engineering Mindset

A flat plate heat exchanger typically has a U value much higher than a shell and tube heat exchanger or a spiral heat exchanger. It creates a compact design. Plate heat exchangers have the same thermal capacity as a shell and tube heat exchanger as much as five times its size. This is because of the combination of high-value heat transfer and.

Schematic diagram of a plate heat exchanger Download Scientific Diagram

Heat exchanger adalah salah satu peralatan penting yang sering ditemukan di lokasi industri. Umumnya, alat ini bisa dimanfaatkan untuk sistem pemanas maupun pendingin.. Plate paling baik digunakan di tempat-tempat seperti pembangkit listrik karena daya tahannya yang kuat dan tingkat perawatan yang rendah. Condensers dan Boiler.

Plate Heat Exchanger Theory PHE Structure and Functional Description

Types of recuperator, or cross plate heat exchanger. A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat.Generally, they are used to extract heat from the exhaust and use it to preheat air entering the.

Plate Heat Exchanger Teknik Elektro

Plate Heat Exchanger adalah penukar kalor yang terdiri dari Pelat (plate) dan Rangka (frame). Pelat disusun dengan susunan tertentu, sehingga terbentuk dua jalur fluida kerja yaitu jalur panas (Hot Side) dan jalur dingin (Cold Side). Hot Side dialiri dengan cairan dengan suhu relatif lebih panas dan Cold Side dialiri dengan cairan dengan suhu.

How Plate Heat Exchangers Work MEP Academy

Heat Exchanger: Pengertian, Fungsi, Jenis, Prinsip Kerja dan Penerapannya. Heat exchanger, atau bisa disebut sebagai alat penukar panas merupakan alat yang berfungsi untuk memindahkan panas antar 2 fluida dengan suhu yang berbeda. Di antara kedua fluida tersebut ada yang berperan sebagai fluida panas dan juga sebagai fluida dingin.

Plate Heat Exchanger (For Dummies) Rasmussen Mechanical

1. Plate Heat Exchanger. Jenis pertama adalah plate heat exchanger yang merupakan jenis paling banyak ditemukan dan umum digunakan untuk industri. Untuk bentuknya sendiri biasanya adalah plate atau lempengan yang ditumpuk sehingga bentuknya berlapis. Pastinya, media yang digunakan dalam pertukaran panas suhu adalah lempengan atau plate itu sendiri.