Charged EVs A closer look at axial flux motors Charged EVs

What is Axial Flux Motor? A motor is a machine that converts the energy of the motor into mechanical energy. Its working principle is based on the electromagnetic interaction of the magnetic field generated by the coil and magnet contained in the structure.

Torque Show How YASA's highefficiency axialflux motors are extending

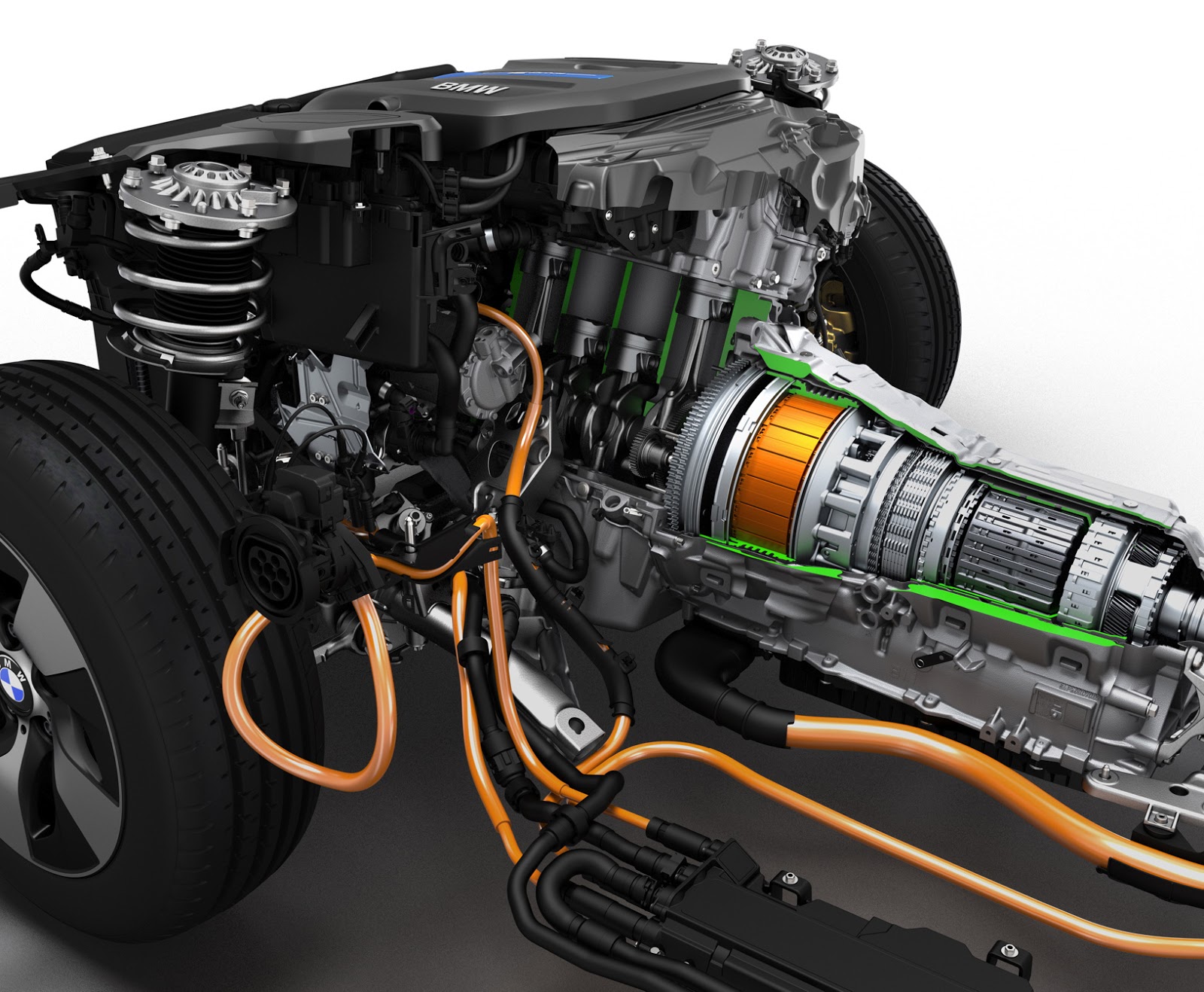

An axial flux motor (also known as an axial gap motor, or pancake motor) is a geometry of electric motor construction where the gap between the rotor and stator, and therefore the direction of magnetic flux between the two, is aligned parallel with the axis of rotation, rather than radially as with the concentric cylindrical geometry of the more.

What Is An Axial Flux Motor And Why Is It Better? Ripple Software

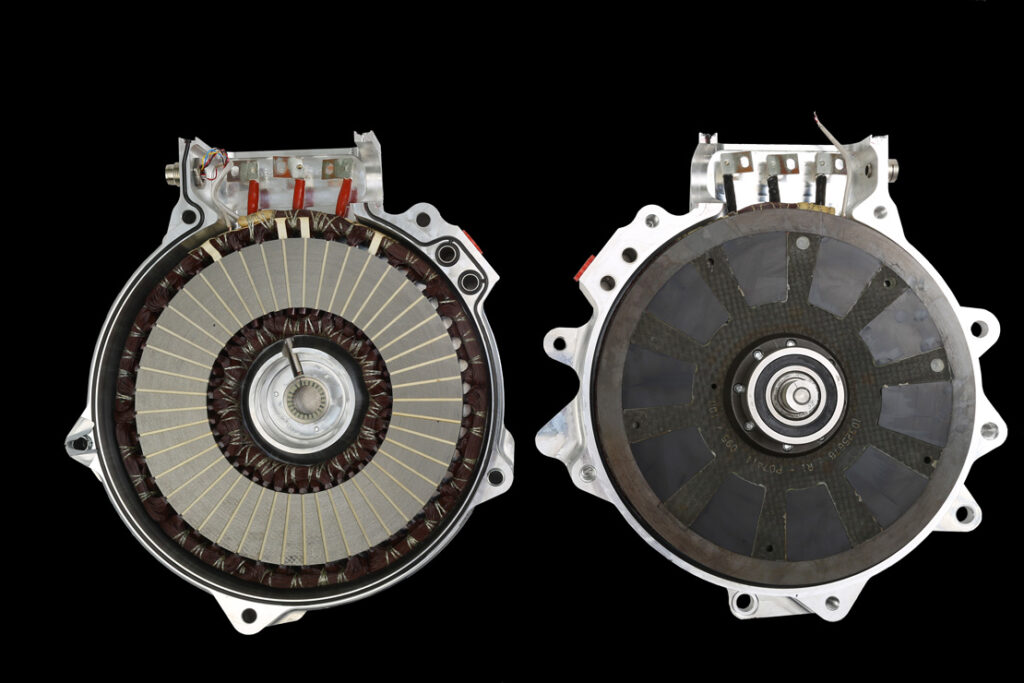

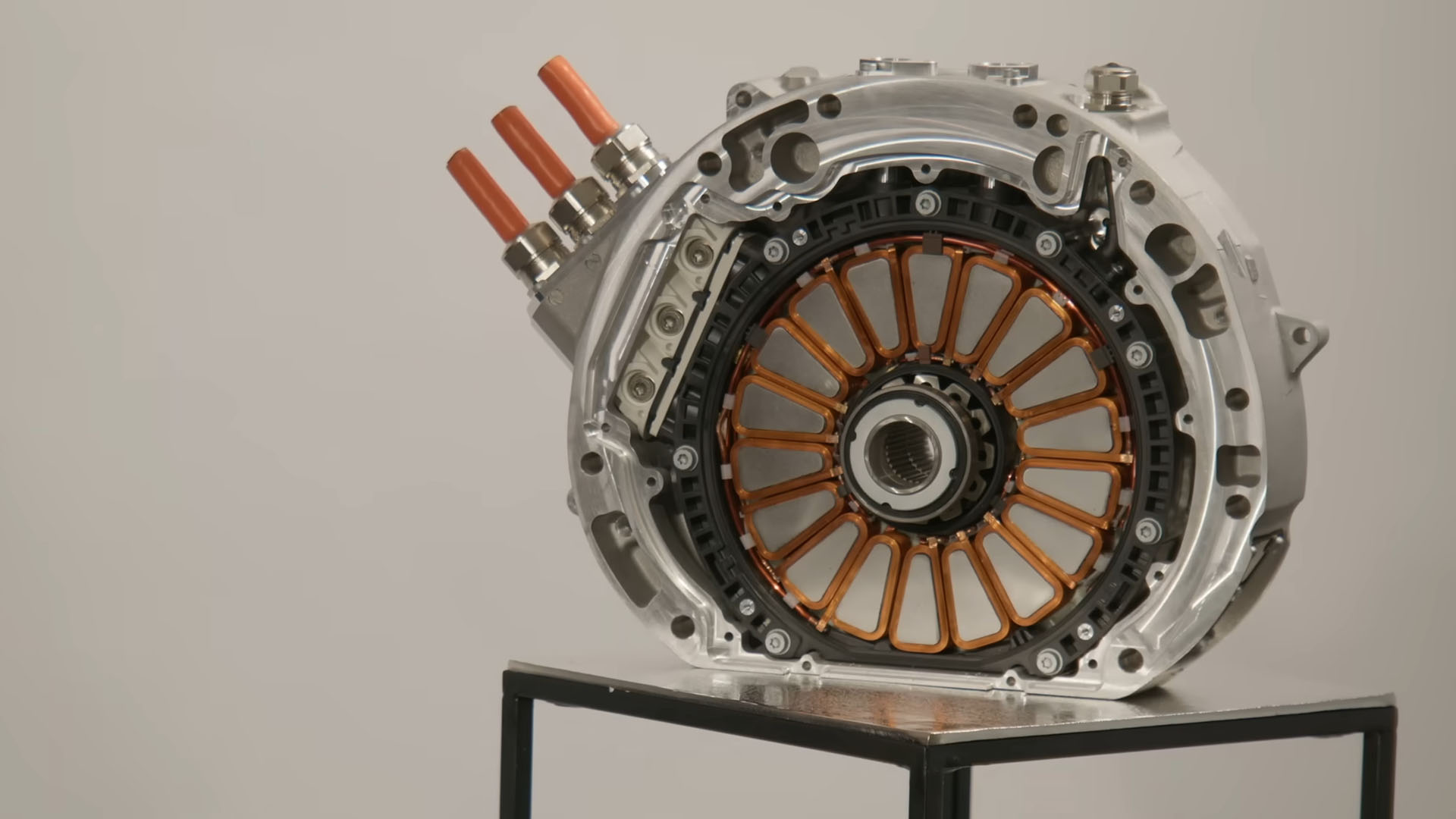

The Infinitum Electric motor is what's known as an axial-flux motor, a design in which the stator's electromagnetic wiring stands parallel to a disk-shaped rotor containing permanent magnets.

Axial Flux Motor Design Provides Increased Torque and Reduced Package

The axial flux motor, sometimes referred to as a 'pancake motor', is a type of electric motor where the magnetic field is aligned along the axis of rotation, hence its name. This structure is in contrast to the traditional radial flux motors, where the magnetic field follows a path along the radius of the motor. Components and Working Principle

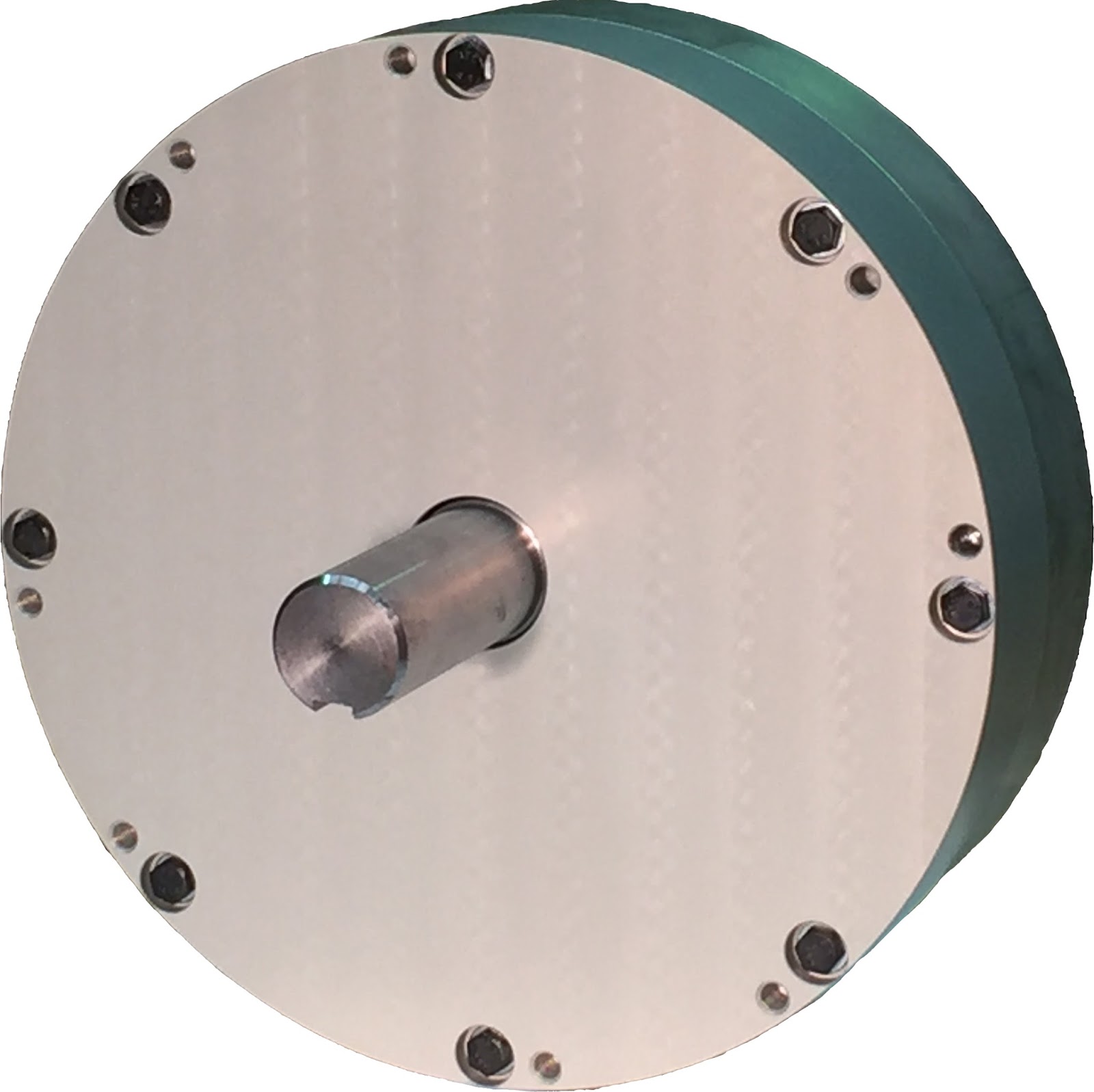

PhiPower PHI301 axial flux motor EMobility Engineering

The axial flux motor is versatile, and the winding can be varied by geometric arrangement according to the design-specific diameter, leading to a significant reduction in the total volume occupied by the machine. Axial flow design also poses some serious design and production challenges: Mechanical Challenges: Due to the strong magnetic forces.

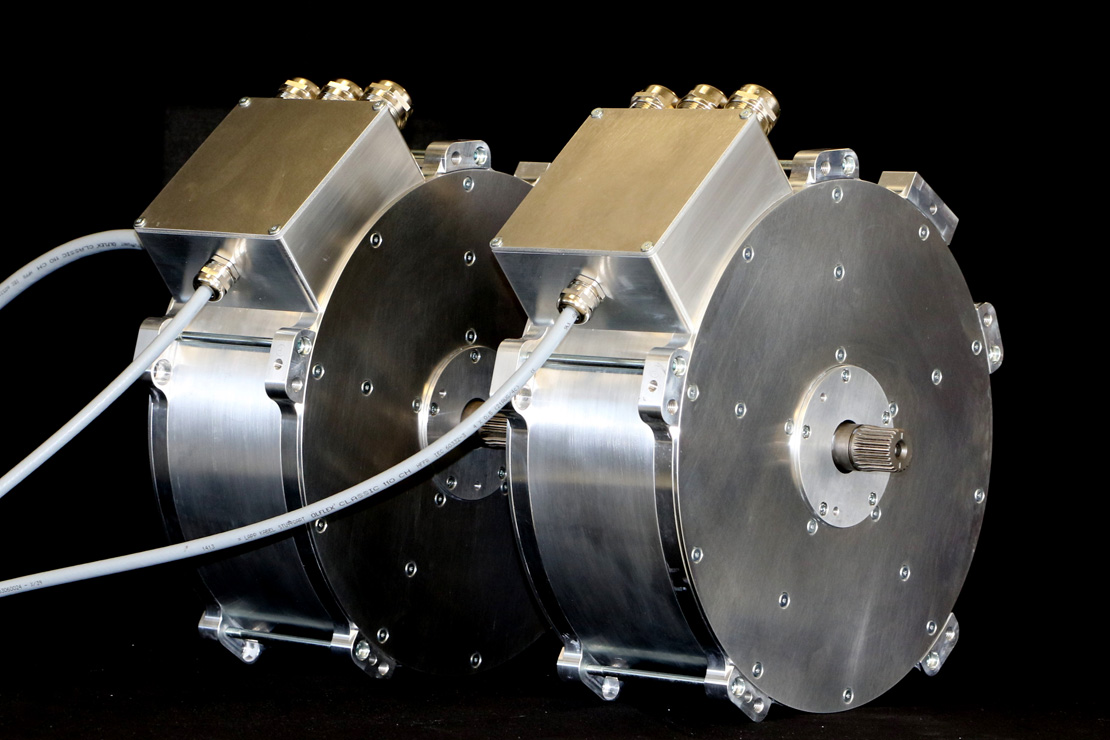

Magnax highpower, compact axial flux electric motor WordlessTech

Axial flux motors, characterized by a unique pancake-like design, have a magnetic flux path parallel to the motor shaft. This configuration results in a compact, lightweight motor with high power density and efficiency. Axial flux motors find significant applications in electric vehicles (EVs) due to their space-efficient design, weight.

Axial Flux Induction Motor for Automotive Applications Electric

Axial-flux permanent-magnet (AFPM) motors are a kind of important motor with compact structure, high power density and high torque density. In this review, the progress of AFPM motors and their key technologies are analyzed and described, with emphasis on the topological structures, design and optimization methods and control techniques.

Axial flux motors EMobility Engineering

In terms of converting electricity into a spinning torque, axial flux motors are about as efficient as standard radial flux machines. The big difference is axial flux's smaller size and.

Magnax prepares to manufacture radically highpowered, compact axial

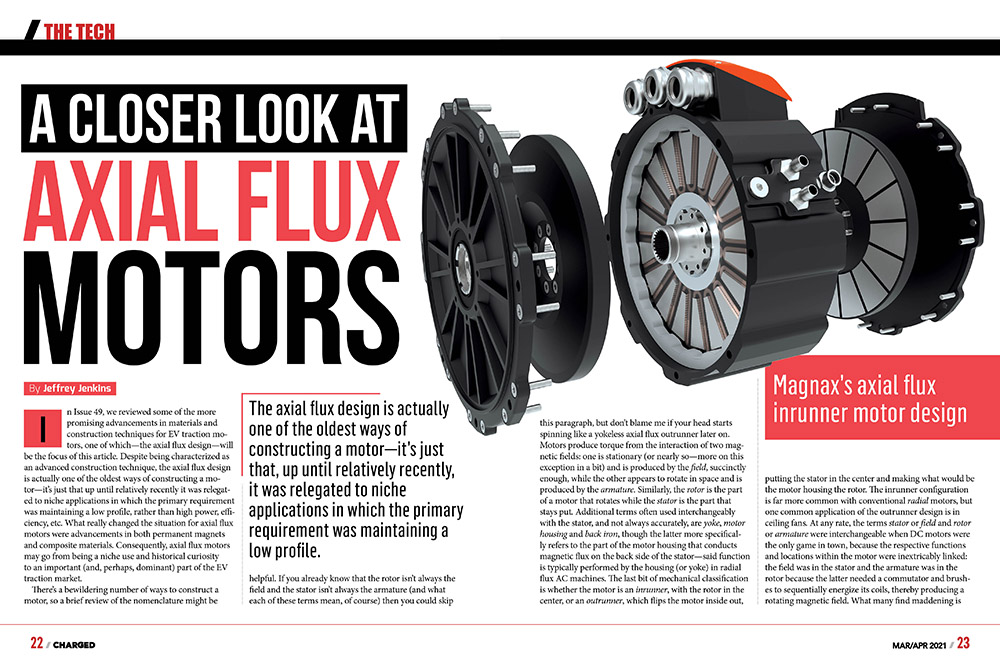

The axial flux design is actually one of the oldest ways of constructing a motor—it's just that, up until relatively recently, it was relegated to niche applications in which the primary requirement was maintaining a low profile. There's a bewildering number of ways to construct a motor, so a brief review of the nomenclature might be helpful.

Axial Flux Induction Motor for Automotive Applications Electric

The Lynch motor, for example, is a type of axial flux motor that dates back to 1979. Usually, the impetus for using an axial flux motor is the ease of construction, but with the right design, they.

Axial Flux Motor Structure Images and Photos finder

It is shown that an axial-flux permanent-magnet machine with one-rotor-two-stators configuration has generally a weaker efficiency than a radial-flux permanent-magnet machine if for all designs the same electric loading, air-gap flux density and current density have been applied.

Designing an Ironless Axial Flux Motor

construction of axial flux machines is the axial attraction between stator and rotor, which is increased by shortening the air gap. This will be more critical in the case of motors, supply their magnetising current from the network, where the air-gap length is implemented as small as possible. The problem almost can be solved using thrust bearings.

Axial Flux Induction Motor for Automotive Applications Electric

YASA axial flux technology has been pushing the performance EV revolution for over 10 years Now, as part of Mercedes Benz, YASA Motors bring up to 4 X more torque and double the power densities of current technologies used in nearly all Electric Vehicles, whilst being 50% lighter and 20% of the depth of a typical radial machine.

Axial Flux Motor Electric Motor Technology YASA Axial Flux Motor

Axial flux permanent magnet (AFPM) motors offer superior power, efficiency, and torque density with their unique flat rotor and stator arrangement. Originally developed for vehicle applications, these motors have seen significant advancements in materials, making them even more powerful and compact. Ongoing research is focused on improving.

Axial Flux Motor Manufacturers

Axial flux motors can change the way a powertrain is designed, moving it from the axle to inside the wheel (Courtesy of YASA) Axial flux motors have many EV design advantages over their radial flux counterparts, as Nick Flaherty explains. Axis of power A new type of motor is gaining traction in the e-mobility sector - the axial flux type.

Why Axial Flux Motors Are a Big Deal For EVs The Drive

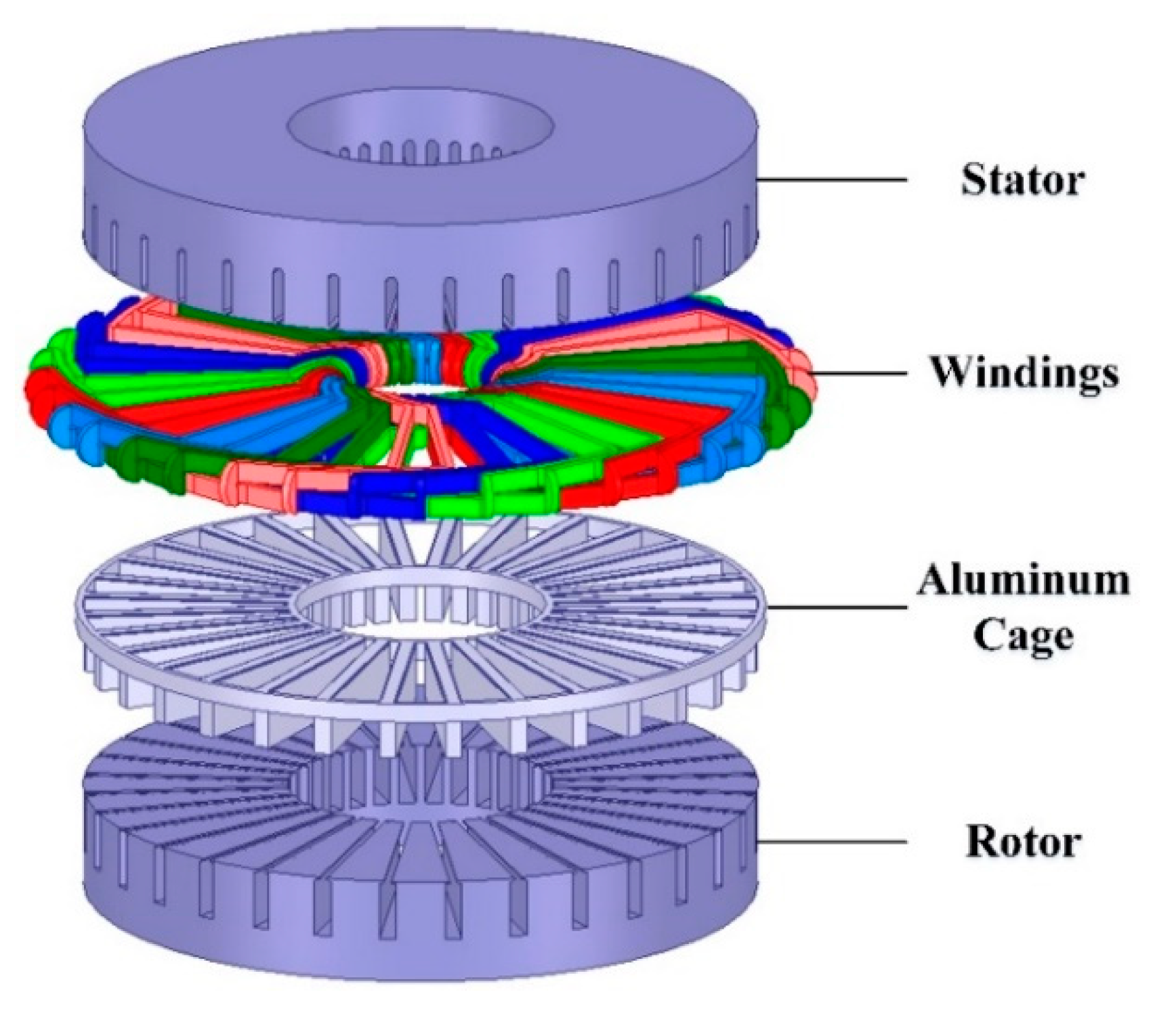

Axial-flux Design, Exploded: This view shows the guts of the Magnax motor, which differs from the traditional layout by putting the one moving part—the rotor—inside the stator. Refinements of this design make it particularly powerful, efficient, and easy to make. Image: Magnax